Add to Cart

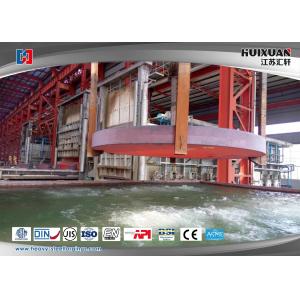

Pressure Vessel Tube Forging Heat Treatment QT 4000MM 20MnMo 20MnMoNb

Products:

Tube plate of pressure vessel QT,tube plate of pressure bearing equipment QT,solid forging round plate QT,forging tube plate QT,tube plate QT,heighten tube plate QT

Products reference:

| Material | 20MnMo,20MnMoNb,16MnD,Q345D |

| Max dia | 4000MM |

| Application | Tube plate after QT are widely used for tube type heat exchanger,boiler,pressure vessel,steam turbine,large scale central air conditioning,etc. |

| Melting process | EF+LF+VD |

| Production process | Forging+heat treatment+rough machining+QT |

| Forging ratio | ≥ 3.5 |

| Applicable standard | ASTM,ASME,DIN,JIS,ISO,BS,API,EN |

| Executive standard | JB/GB/EN/DIN/JIS/ASME/ASTM/ISO |

| Certification authority | ISO,BV,SGS, IST, UL,CTI |

| Inspection | Plant self inspection or third party inspection,shipment after all items are qualified |

| Delivery term | Rough machining(N+T);finish machining(Q+T) |

| Test equipment | Spectrograph,UT device,tensile and compact test machine,metalloscope,outside micrometer,bore dial indicator,hardness test machine |

| Service | Our service included the forging, process, heat treatment, finish machining, package, local logistics, customers clearance and maritime transport. We took the customer’s requirements as the principal thing, and pay attention on the products quality. |

Custom properties

| Material elements | C | Si | Mn | P | S | Cr | Ni | Mo | Nb |

| 16MnD | 0.13-0.20 | 0.17-0.37 | 1.20-1.60 | ≤0.030 | ≤0.030 | ≤0.30 | ≤0.30 | -- | |

| 20MnMo | 0.17-0.23 | 0.17-0.37 | 1.10-1.40 | ≤0.025 | ≤0.015 | ≤0.030 | ≤0.030 | 0.20-0.35 | |

| 20MnMoNb | 0.16-0.23 | 0.17-0.37 | 1.20-1.50 | ≤0.035 | ≤0.035 | -- | -- | 0.45-0.60 | 0.20-0.45 |

| Mechanical property | Dia.(mm) | TS/Rm(Mpa) | YS/Rp0.2(Mpa) | EL/A5(%) | RA/Z(%) | Type Of notch | Impact energy | HBW |

| 16MnD | Ø10 | 470-630 | ≥345 | ≥21 | -- | V | -20℃≥34 | -- |

| 20MnMo | Ø10 | ≥605 | ≥475 | ≥25 | -- | V | ≥180 | -- |

| 20MnMoNb | Ø10 | ≥635 | ≥490 | ≥15 | -- | U | ≥47 | 187-229HBS |

Process procedure:

Forging process flow quality control:

Commerce clause

| MOQ | 1PC |

| MAX weight | 30T |

| Delivery time | 10-60 days |

| Package | wooden pallet,steel frame |

| Delivery term | FOB;CIF;CFR;DDU; |

| Payment term | T/T,LC |

| Type of shipping | By ocean,air |

Advantage